Customizable Industrial Computing Platforms

Hybrid Architecture × Military-Grade Reliability

Technical Parameter Matrix

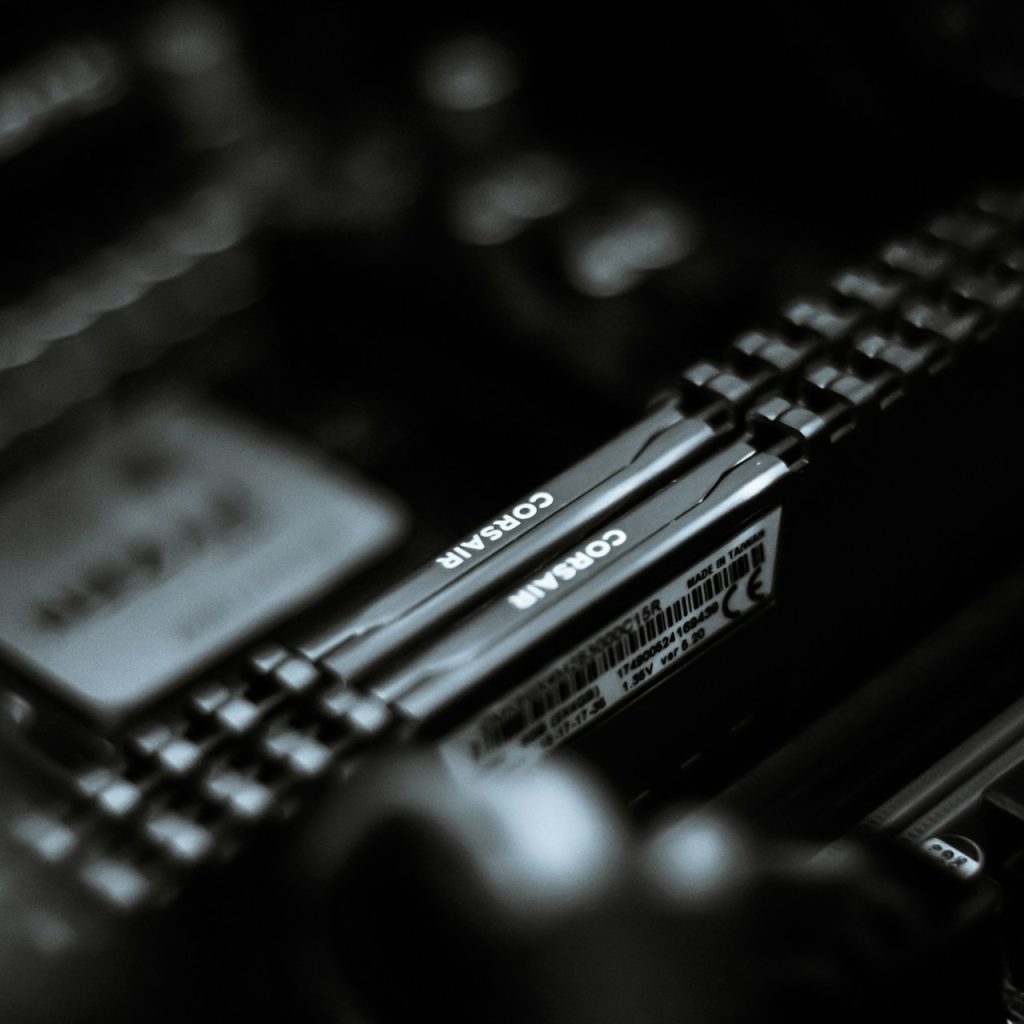

Hardware Configuration

CPU

Dual-platform options: Intel 12th Gen i7/i5 or AMD Ryzen 7, ARM architecture expansion modules require separate configuration.

Industrial Interface

-

Communication Interface

SIM Slot (Pre-installed for 4G Module) + Triple-isolated COM Port (COM1/485 Jumper-selectable)

-

Control Bus

Isolated RS-485×4 (2500V<sub>rms</sub>) + CAN Bus×2 (w/ Terminating Resistor Jumper)

-

Expansion Capability

PCIe 3.0 x4 Slot (FH/HL compatible) + GPIO 16-ch (5V/12V Programmable)

Reliability Verification

Military-Grade Protection Design

Operating Temp: -40℃~85℃ Continuous

Intelligent Management Suite

Dual-mode Watchdog: HW Reset Circuit + SW Heartbeat (min.50ms)

Application Scenario

Standard Config: Core i5 + 16GB RAM + 4×CAN Bus

Function: Real-time AGV Dispatch Control (Linux RT Kernel Optimized)

Standard Config: AMD Embedded CPU + 8GB ECC RAM + RS-485 Hub

Function: Modbus-TCP Gateway for Substation Device Clusters

Customization Process

Execute on-site operational mapping, quantify vibration/temperature-humidity/EMI parameters. Synchronize interfacing with PLC protocol stacks and SCADA system specifications.

01. Diagnostic Survey Requirement

Based on TCO (Total Cost of Ownership) model, compare x86 vs ARM architectures for real-time/power/computing trade-offs. Determine heterogeneous computing topology.

02. Architecture Selection

Perform 72-hour HALT (Highly Accelerated Life Testing) at certified 3rd-party lab. Expose latent design flaws (e.g. PCB deformation at 85℃/95%RH).

03. Environmental Testing

Deploy to customer's operational line for MTBF testing. Collect data to demonstrate compliance with ISO 13849-1 PLc safety level.

04. Prototype Validation

Implement serialized traceability management. Each unit includes dedicated test report and EMC (Electromagnetic Compatibility) certification copy.